Description

RAISE3D Pro2 3D Printer – 12″ x 12″ x 11.80″ Build Size – Fused Filament Fabrication – Double Jet – 0.4 mil Layer – 68.9 mil Filament – Acrylonitrile Butadiene Styrene (ABS), High Impact PolyStyrene (HIPS), Thermoplastic Polyurethane (TPU), Thermoplastic Elastomer (TPE), Nylon, Wood, Polylactic Acid (PLA) Supported – Network (RJ-45) – Wireless LAN

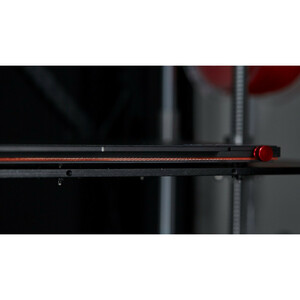

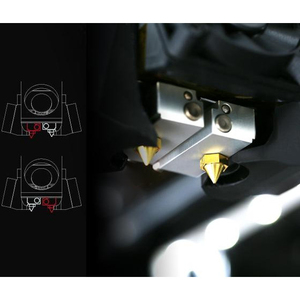

Electronic Driven Dual Extrusion with Retracting Nozzles

Prints complex mechanical parts, supports a variety of multi-material filaments and improves print speed.

High repeatability (<0.005m, 5 micron).

Light speed (<1 second switching time).

1.5mm lifting distance, compatible with flexible filaments.

Reliability tested over 100,000 times!

Big Build Volume

24/7 Reliability – Multiple Fail Safe Systems – Industrial Grade Components

For Material Compatibility up to 300?

PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA

PP / Glass Fiber Enforced / Carbon Fiber Enforced

Metal Particles Filled / Wood Filled

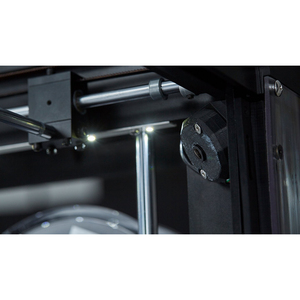

High Resolution

Unique motion system for superior part quality and resolution.

Unmatched layer resolution: 0.01 layer thicknessPrecise positioning: 0.0125mm positioning resolution on x/y axis

Intuitive User Experience

7-inch touch screen.

Visual interface / Rapid reviewing / Visual print progress / Full adjustment control

Second Generation Power Loss Resuming

Never lose a print.

“I actually knocked off the power accidentally when i hit the cord when I was vacuuming, I was currently doing a 96 hours print with only 2 hrs left. As I raised my head to scream in terror, I turned back on the machine and it asked me to continue print…THIS WAS A LIFESAVER”by Shon Robinson

Remote User Interface

Operate efficiently with ideaMaker by connecting wirelessly to your Pro2 Series Printer.

Built-in camera.

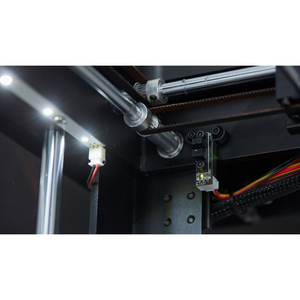

Next Generation Motion Controller

Top reliability. Accurate current control. Silky smooth movement. Superior thermal performance.

400MHz ARM Cortex-M7 32bit RISC FPU.

Industrial grade components.

Standalone motor driver.

256 micro-steps driver system.

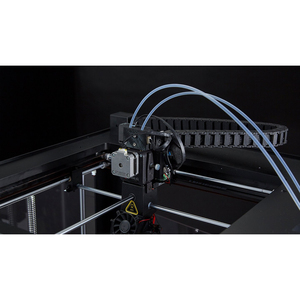

New Extruder with Filament Run-Out Sensor

Better grip. No slipping. Worry free prints.

Dual gear driven extruder.

4× increased torque performance.

Fluent and sensitive, optical run-out sensor.